- Home

- Sustainability

- Shipping Business Initiatives

Shipping Business Initiatives

The Shipping Business of Meiji Shipping Group handles the entire life cycle of vessels from shipbuilding to scrapping. During each and every stage, we focus not only on safe operation but also preserving the environment.

Our Ship Owning Business owns a wide range of almost every kind of vessels, namely from LNG/LPG tankers, very large crude oil carriers, product tankers, chemical tankers, pure car & truck carriers, large containerships, wood chip carriers and to bulk carriers. This diversity of vessels allows us to sustain a balanced fleet resilient to market fluctuations and shifting demand between the various sectors. Meiji Shipping enters into medium to long-term time charter agreements carrying oil, gas, iron ore and other major resources by chartering its own vessels out to leading shipping companies and resource majors worldwide for their trading. Supported from both land and sea, our Ship Management Business is founded on technology that systematically maintains the long term high-level of safety which is generally demanded of oil tanker management. Our eco-friendly and safety-oriented approach is highly regarded for providing high-quality ship management capabilities and many domestic and overseas ship owners entrust their ship management to us.

In 2018, we established MK Maritime Training Center, a training facility for seafarers in Manila, the Philippines aiming to employ and train several thousand seafarers in a country which still has significant economic and living disparities. The facility supports the livelihood of the seafarers and their families while training our crews to a high level with a high sense of safety to sail on our own vessels and those under our management.

- Social Initiatives

- Environmental Initiatives

Human Resource Development and Employment in the Philippines

Our Ship Management Business provides ship management services to customers around the globe from bases in Tokyo, Singapore, Manila and India.

In 2018, we opened MK Maritime Training Center, a training facility for seafarers in the Philippines and invited cadets from all over the nation to realize high-quality seafarer training and education. As of 2022, we employ approximately 3,500 Filipino seafarers and approximately 2,000 Indian seafarers who work on vessels we own and/or manage. Our training program includes pre-boarding training, career promotion seminars, practical workshops using a full-scale facility with state-of-the-art ship-handling and engine simulators, an Electronic Chart Display and Information System (ECDIS), and actual generators. Everything is managed by Meiji Shipping Group in the Philippines, which is a major employment hub for seafarers.

Our seafarer training facility boasts a site area of approximately 17,000 m2 and a building floor area of about 7,000 m2 and accommodation, which enables us to train a total of approximately 5,000 seafarers annually. The facility makes it possible to prepare for future expansion of vessels under our management and support the external demand for seafarer training.

The operation of a large-scale training facility in the Philippines and the jobs it creates help revitalize the region as well as supports the seafarers and the families who depend on them.

To ensure the safe and efficient operation of our IGF (International Code of Safety for Ships Using Gases or Other Low-Flashpoint Fuels) vessels, our group company /MMS Co., Ltd. (Ship Management Company) has initiated an in-house Basic IGF course January 2024 with approval from the MARINA (Maritime Industry Authority) in the Philippines at our Manila Training Facility. Recognizing the paramount importance of well-trained human resources in the maritime industry, this initiative aims to equip our seafarers with the necessary skills for the responsible operation of IGF vessels.

The state-of-the-art simulator training program of MMS Co., Ltd. stands as a cornerstone in our efforts. This program ensures that our seafarers attain a profound understanding and the required knowledge for operating IGF vessels,reinforcing our commitment to safety, efficiency, and environmental stewardship.We remain steadfast in our dedication to expanding our footprint in cleaner fuels and, in doing so, contributing to a greener and more sustainable future.

Training and Employment of Female Seafarers

The Ship Management Business of Meiji Shipping Group has begun training and recruiting female seafarers in India as of 2020. As of 2022, ten female seafarers are onboard our managed vessels and playing an active role on vessels under our management. We plan to continually increase the number of female seafarers in the future.

Our work to recruit female seafarers has only just begun by actively hiring and providing equal opportunities to female seafarers. We have improved onboard working environments and operational efficiency in ways that we had not noticed before. We will always strive to build a working environment that empowers female seafarers to actively participate as part of the crew now and into the future.

Initiatives to Promote Better Health on Long Voyages

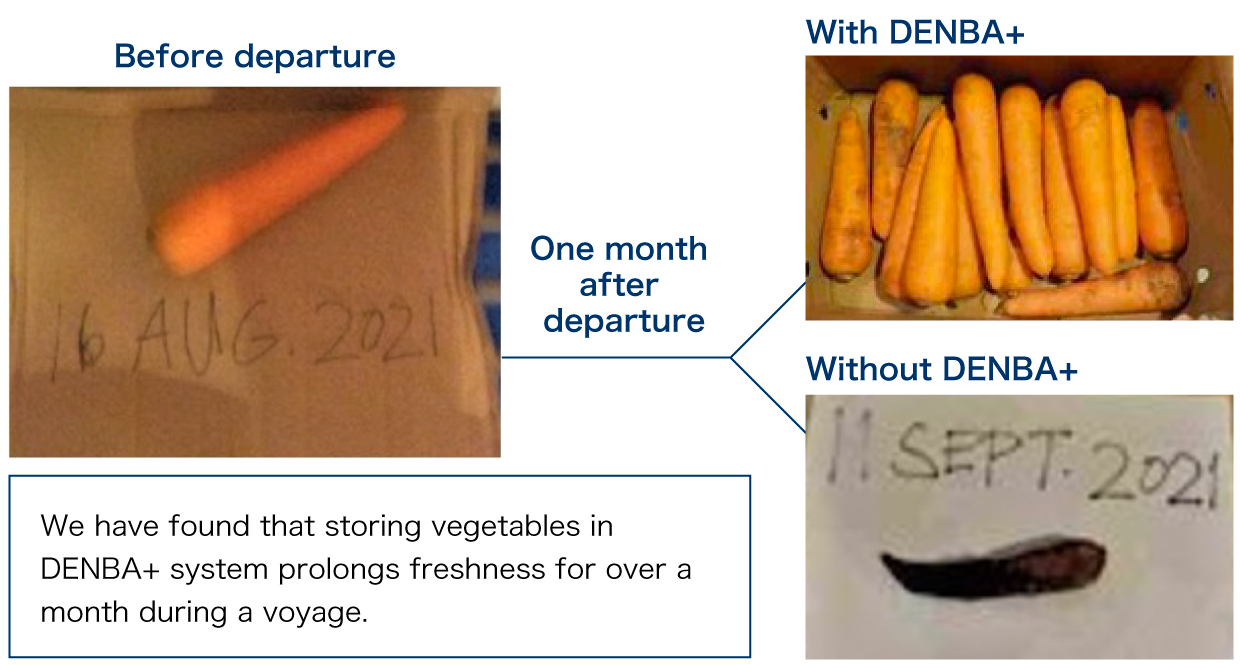

Seafarers sailing on long voyages not only maintain their physical and mental health through a proper diet but also should enjoy the meals they eat throughout while onboard. However, the difficulty in keeping food fresh on a ship presents a challenge. Freezing and refrigeration technologies have come a long way but vegetables go bad in about two weeks while meat and fish lose much of their flavor.

Our Ship Management Business had introduced a new cold storage system called DENBA+ (DENBA Corporation) technology to prolong the freshness of foods. This system leverages proprietary technology to realize a chilled environment as low as -4℃, which prolongs food freshness. Unlike freezing, this type of refrigeration keeps food flavorful because it does not damage the cells.

Eating fresh food during a long voyage effectively enhances crew motivation and promotes better health. Meiji Shipping Group will further broaden its adoption of these kinds of technologies in the future.

Community Engagement

The Meiji Shipping Group has carried out a wide range of volunteer activities with local communities where it has business establishments.

As an example in the Philippines, our Group has been participating in a cleanup effort around Manila Bay since 2008.

We have also been hosting regular tree planting events since 2011 as one of the environmental conservation initiatives.

In response to any serious damage caused by typhoons or other natural disasters, our Group also provides monetary support as well as donating relief supplies.

Formulation of Vision Toward Carbon-free Society: A Shift to Net-Zero GHG Emissions by 2050

The Shipping Business of Meiji Shipping Group consists of the Ship Owning Business which handles the acquisition of vessels, and the Ship Management Business which maintains and manages both in-house and third-party vessels as well as recruiting and training crew. With those major functions, we rent out our vessels through time charter agreements with leading shipping companies and resource majors worldwide dealing primarily in oil, gas, iron ore, and other major resources.

As a listed global company, we also play an important role in providing information to support our customers for their needs. In light of calls to reduce GHG emissions, we, as a pure tonnage provider, are to support our customers in reducing their GHG emissions from those vessels they charter and operate. To this end, we believe it is important to coordinate with our customers to encourage the adoption of the eco-friendly equipment and systems outlined below, while increasing the ratio of ships in our fleet that have low impact on the environment as much as possible. As a shipping conglomerate with ship ownership at its core, our basic policy is to retain our own vessels over a long period of time with a long-term view. This creates a long cycle until a ship becomes scrap, which in turn helps reduce our environmental impact.

Adoption of Eco-friendly Equipment and Systems

LNG Carrier in Service

In 2019, we acquired and started managing a membrane-type LNG carrier with a capacity of 174,000 m3. This ship is equipped with the latest X-DF dual fuel low-speed engine that utilizes both typical fuel oil and BOG*. The engine is an eco-friendly engine that reduces carbon dioxide (CO2) emissions by approximately 30% compared to typical fuel engines. The technology even reduces nitrogen oxide (NOx) emissions by up-to 80% percent while nearly eliminating all sulfur oxide (SOx) emissions.

*BOG: Boil Off Gas (Natural Vaporized Gas)

Methanol Tankers in Service

In 2022, we acquired and began operating two MR-sized methanol tankers. These methanol tankers are equipped with a dual fuel low-speed engine that enables the vessels to be powered by not only standard fuel oil but also by methanol, which has a lower impact on the environment.

When the ship is using methanol as its fuel, the engine can reduce sulfur oxide (SOx) emissions by up to 99%. Methanol fuel also ensures the sulfur concentration in the fuel oil stays below 0.5% as per the regulations put in place by the International Maritime Organization in 2020. We hope to use methanol as an eco-friendly fuel because it ensures lower emissions of other harmful emissions, such as nitrogen oxides (NOx) and particulate matter (PM), than conventional fuels.

Shipping Service for Low-carbon Solutions

As a member of the supply chain for low-carbon solutions, the GREEN GENIE Ultramax bulk carrier built in 2020 operates on a long-term contract carrying wood pellets from various sources around the world to biomass power plants in Japan.

Safety Navigation Support System Using AI Analyses

Marine safety to protect human life and the environment is our top priority. We even have one LNG carrier equipped with an ORCA AI System. This system uses six cameras, including thermal cameras, to gather visual information about the surroundings at night, in rain or fog, or in other situations where visibility is poor. The system combines and displays this visual information on a single screen alongside data acquired from the AIS*, radar, GPS, gyrocompass, and other ship equipment. The platform also has a function to alert navigators of any potential collision dangers. The various AI analysis and consolidates information, which assist in the decision-making of these navigators as well.

*AIS: Automatic Identification System

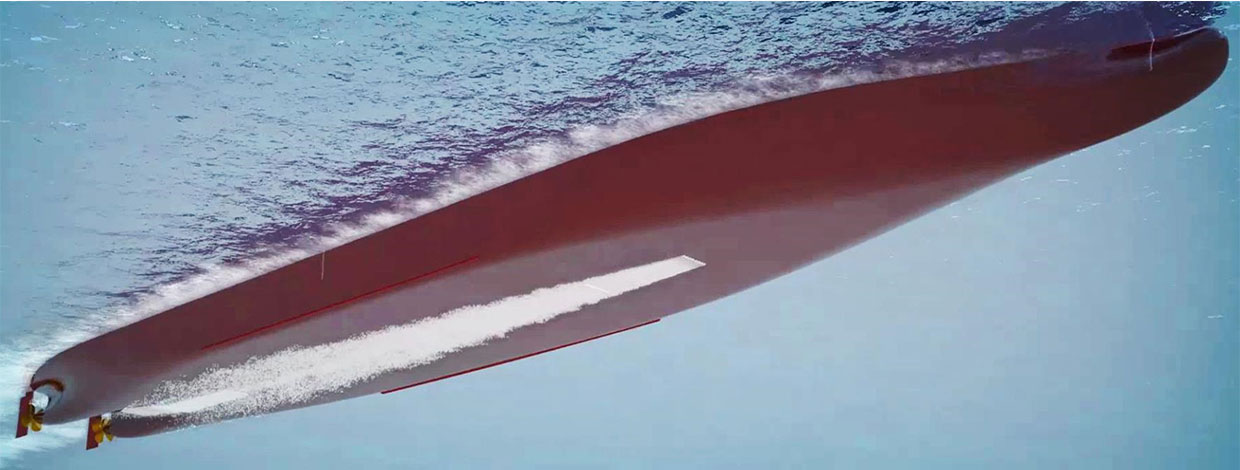

Air Lubrication System Saving Energy on Ships

The Meiji Shipping Group is committed to using innovative technology in an effort to further reduce its carbon emissions in accordance with the IMO Energy Efficiency Design Index (EEDI) Phase III levels. As a shipowner pioneering these types of technologies, we have equipped each of our two large LNG carriers with an Air Lubrication System (ALS), a system that creates a carpet of microbubbles under the hull of the ship to reduce water resistance. The lower resistance enhances the energy efficiency of the ship and reduces fuel consumption and CO2 emissions when transporting cargo between ports by up to 6%, which is equivalent to 18 tons of CO2 per day. YouTube Link 1 and Link 2 below provide information about the ALS used on these two carriers.

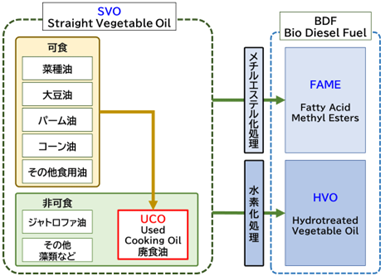

Operation with fuel blended with biofuel (FAME)

We are pleased to announce the successful operation of our Ro-Ro vessel using biofuel, specifically FAME (Fatty Acid Methyl Ester), with a blending ratio of 28% as marine fuel. This biofuel initiative not only contributes to the reduction of carbon dioxide emissions but also stands as a proactive step towards decarbonization in the future. Moving forward, we remain committed to making further contributions to environmental sustainability and reducing our ecological footprint. We look forward to continuing our efforts for a greener and more sustainable future.

(Source: Guidelines for Handling the Use of Biofuels on Ships by the

Ministry of Land, Infrastructure, Transport, and Tourism of Japan.)

LNG Reliquefication System

Our two LNG carriers are equipped with a system that can reliquefy up to 60% of LNG BOG*. This BOG is burned while the vessel is waiting at harbors or ports, or passing through canals. A reliquefication plant compresses and reliquefies and returns BOG to the LNG tank, which reduces CO2 emissions and protects the environment. This system enables us to reduce CO2 emissions by up to 60% while a vessel is waiting at harbors, ports, or passing through canals. These reductions are equivalent to roughly 190 tons of CO2 per day.

*BOG: Boil Off Gas (Natural Vaporized Gas)

Adoption of Ultra-Low Friction Antifouling Paint

The Meiji Shipping Group uses next-generation ultra-low-friction antifouling paint as part of its effort to provide more efficient shipping operations. The adoption of this paint reduces fuel consumption by about 5% in addition to lowering CO2 emissions. We will continue to adopt new innovative and energy-saving technologies for a greener planet in the future. This is equivalent to a reduction of 13 tons of CO2 emissions per day from just one of our VLCCs*

*VLCC: Very Large Crude Carrier (Deadweight of 200,000 Tons or More)

Installation of Scrubbers

As an initiative to comply with regulations ahead of the 2020 SOx restrictions, the Meiji Shipping Group equipped two vessels with scrubber technology that reduces SOx emissions and controls air pollutants. We plan to also actively equip our vessels with new technology toward future environmental conservation.

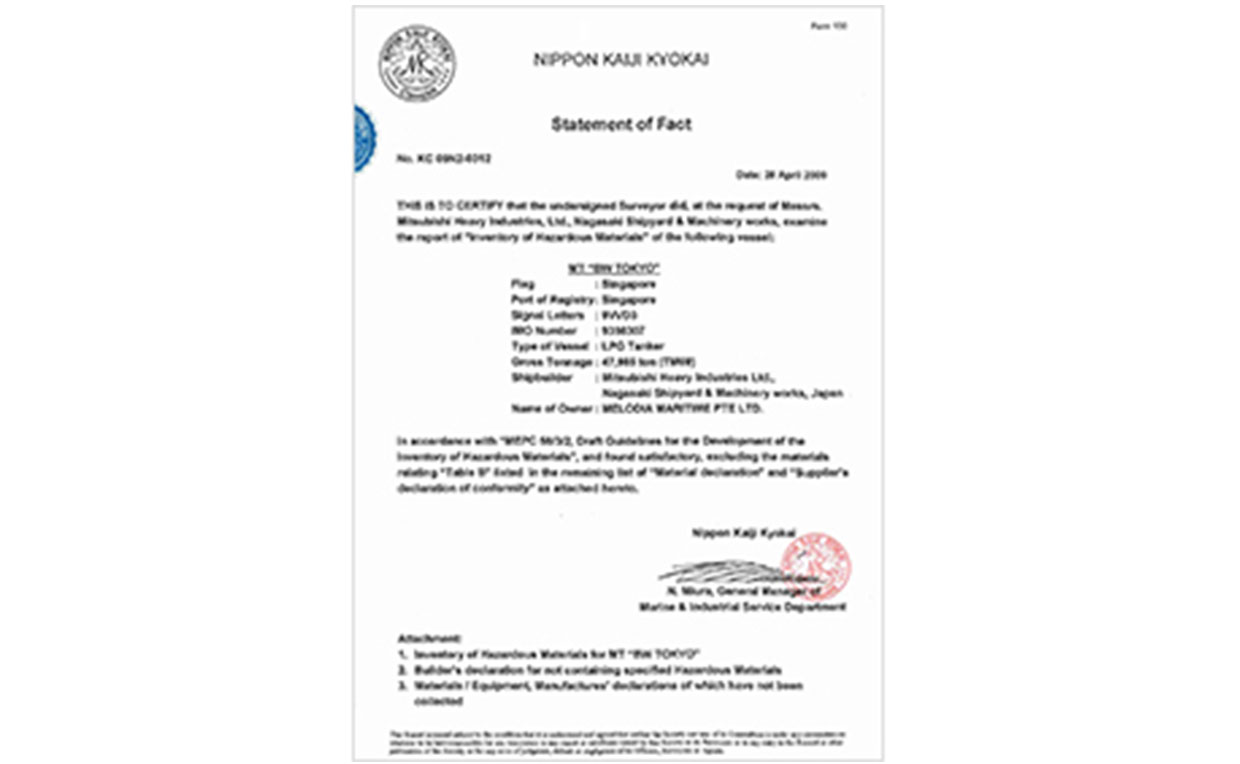

In Anticipation of the Ship Recycling Convention

The Meiji Shipping Group built its first B.W. TOKYO LPG very large gas carrier in 2009 in anticipation of the Ship Recycling Convention* set to go into effect in the next several years. This ship is the first NK class vessel to issue an inventory of hazardous materials (IHM), which identifies the amount and location of hazardous materials onboard the ship, and receive a ship recycling license. As the shipbuilders, Mitsubishi Heavy Industries and ClassNK launched teams to issue this inventory and comply with the Ship Recycling Convention. The two teams worked together and put in place a comprehensive system to satisfy our requirements for this vessel in the first initiative to build a ship of this kind in Japan.

*The Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships adopted in May 2009 (Ship Recycling Convention)

Installation of Solar Power Generation System

Our group company based in the Philippines has implemented a solar power generation system. The installation covers a total area of 1,259 m², with a maximum generation capacity of 182.65 kW per hour. By utilizing renewable energy, this system is expected not only to reduce electricity costs but also to contribute to reducing environmental impact such as lowering CO₂ emissions.

Unique Meiji Shipping Group Measures to Control Pollution

As a Meiji Shipping Group company, MMS utilizes its own unique method for Oil Contamination Monitoring (OCM) in an effort to prevent marine pollution. Regulations prohibit any oily water passing through an oil separator with a concentration of 15 ppm or more from being released into the sea, and requires each vessel to store the contaminated water onboard. However, MMS uses its unique eco-friendly method to incinerate any oily water with a concentration of 15 ppm right on the ship.